FROM DESIGN TO OPERATION

FROM DESIGN

TO OPERATION

FROM DESIGN

TO OPERATION

Since 1984, Pan American has been a global provider of energy solutions. Pan American specializes in providing a portfolio of proprietary technologies for distributed production of renewable hydrogen, renewable natural gas and carbon capture. By focusing on responsible renewable gas generation.

Pan American is helping customers around the world reduce their operating costs while reducing their carbon footprints.

Pan American offers 40 years of experience developing highly reliable hydrogen generators using a variety of feed gases, including biogases to provide hydrogen with purities up to 99.999%. Pan American’s units can economically replace your dependence on liquid hydrogen supplies from third party retailers, giving you independence and security in your hydrogen requirements.

Headquartered in Brownsville, TX. Pan American has a worldwide presence teaming up with 6 manufacturing facilities, and four sales offices spanning over four continents.

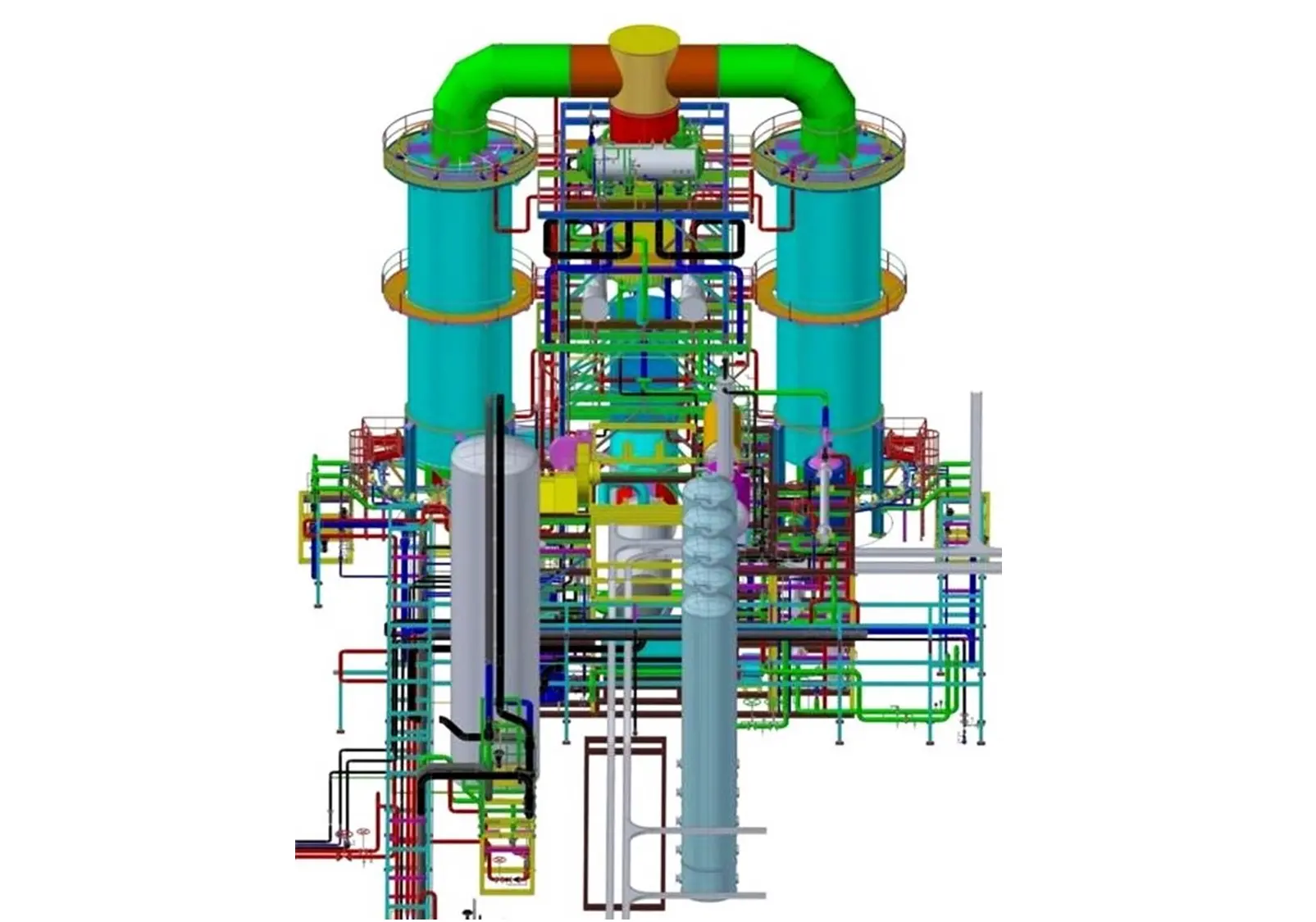

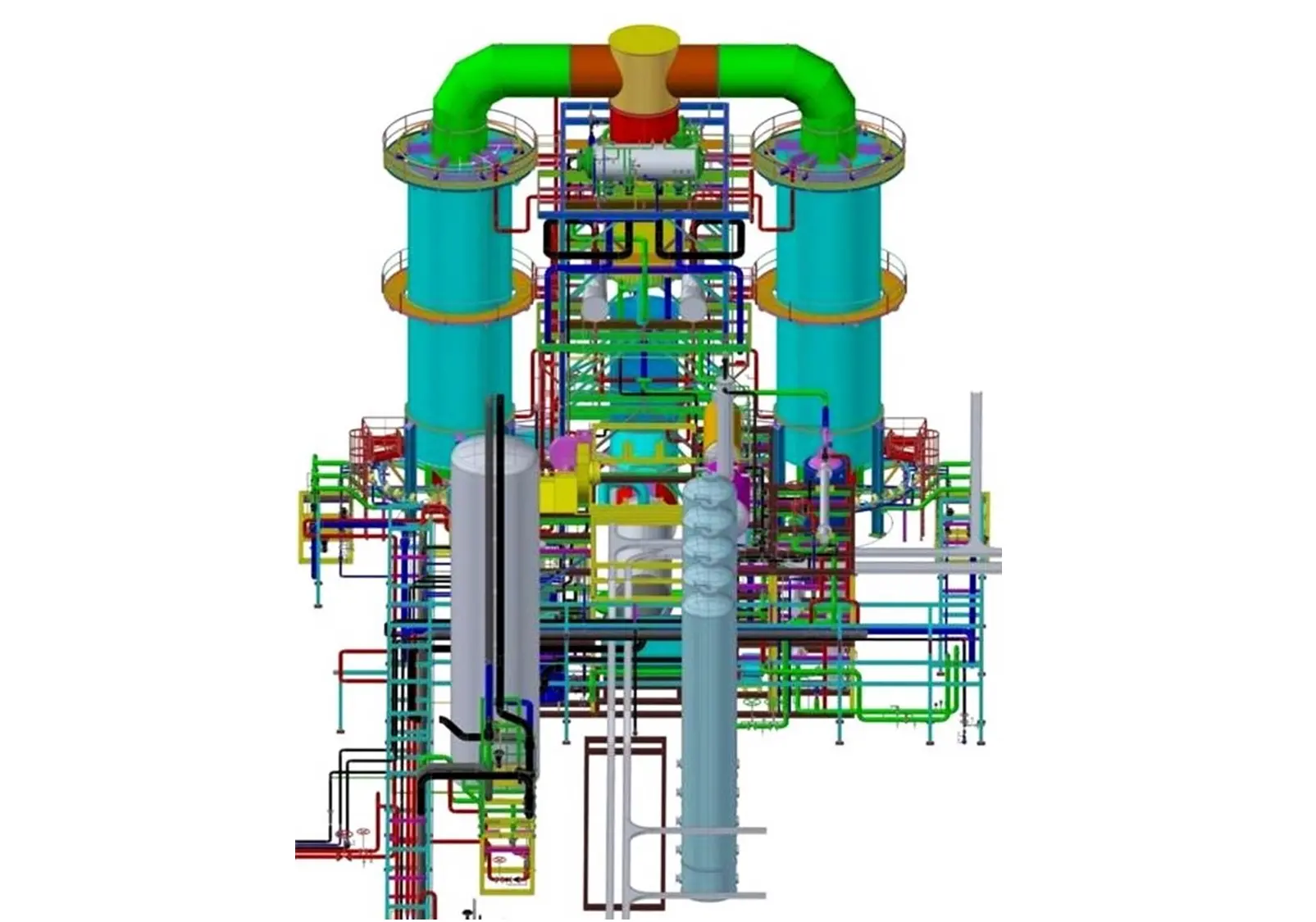

Pan American designs Hydrogen Steam Methane Reforming (SMR) Plants that have a production capacity from less than 1.0 tons/day to 30.0 tons/day (100 Nm3/h to 15,000 Nm3/h) of high purity hydrogen from natural gas, LPG, naphtha and biofuel feedstocks. The Hydrogen is produced by catalytically reforming natural gas or any other hydrocarbon feedstock with superheated steam at elevated temperatures in the vertical cylindrical reformer furnace. More hydrogen is produced by a reaction of carbon monoxide and steam in the shift converter. Impurities in the hydrogen stream such as carbon monoxide (CO), carbon dioxide (CO2), methane (CH4) and water (H2O) are removed by the HPU adsorption system, thus producing ultra pure hydrogen.

Plants have the following hydrogen product specifications:

• Pressure: 14 Barg

• Temperature: 38° C

• Dew Point: -56° C

• Purity: 99.9995 % vol.

40 years’ experience custom building hydrogen plants to user specifications.

Pan American designs Steam Methane Reforming (SMR) plants for the production of hydrogen with a team of engineers using upgraded proprietary technology, applied successfully on more than 50 hydrogen plants around the world.

Pan American plants are designed with international standards such as ASME, SAE, CE, UL and others.

Pan American has successfully used PLC, SCADA and DCS controls as such as: Delta V system ®, Allen Bradley ®, Siemens ® and others. These systems work with a single integrated database for all signals, variables, graphical objects, alarms and system events. The programming platform is multi-user so that several programmers can work simultaneously on the secure system without version conflicts. All system equipment (computers, servers, controllers) is synchronized, so that all measurements, alarms and events have the same timestamp. The system control software has tools for managing the plant information, integrating it vertically into the decision-making chain. Our control system accommodates loop checking for the process control systems prior to field installation.

Pan American manufacturing facilities are fully integrated with their quality management structure. Systems are in place for inventory control and welding quality control, including associated documentation for certified welders and associated testing for high pressure vessels and structures.

Pan American works under ASME "U", "R" and "S" stamps.

Pan American has the experience and logistics to negotiate or arrange agreements with our clients or transportation from the manufacturing facilities to the assembly site over long distances by sea or land, subject to the legal provisions that must be met.

Over these 40 years, Pan American has accumulated the skill and experience to manufacture its plants in modular form, so that they can be assembled at the production site in manner, saving human resources and time.